Story Vision

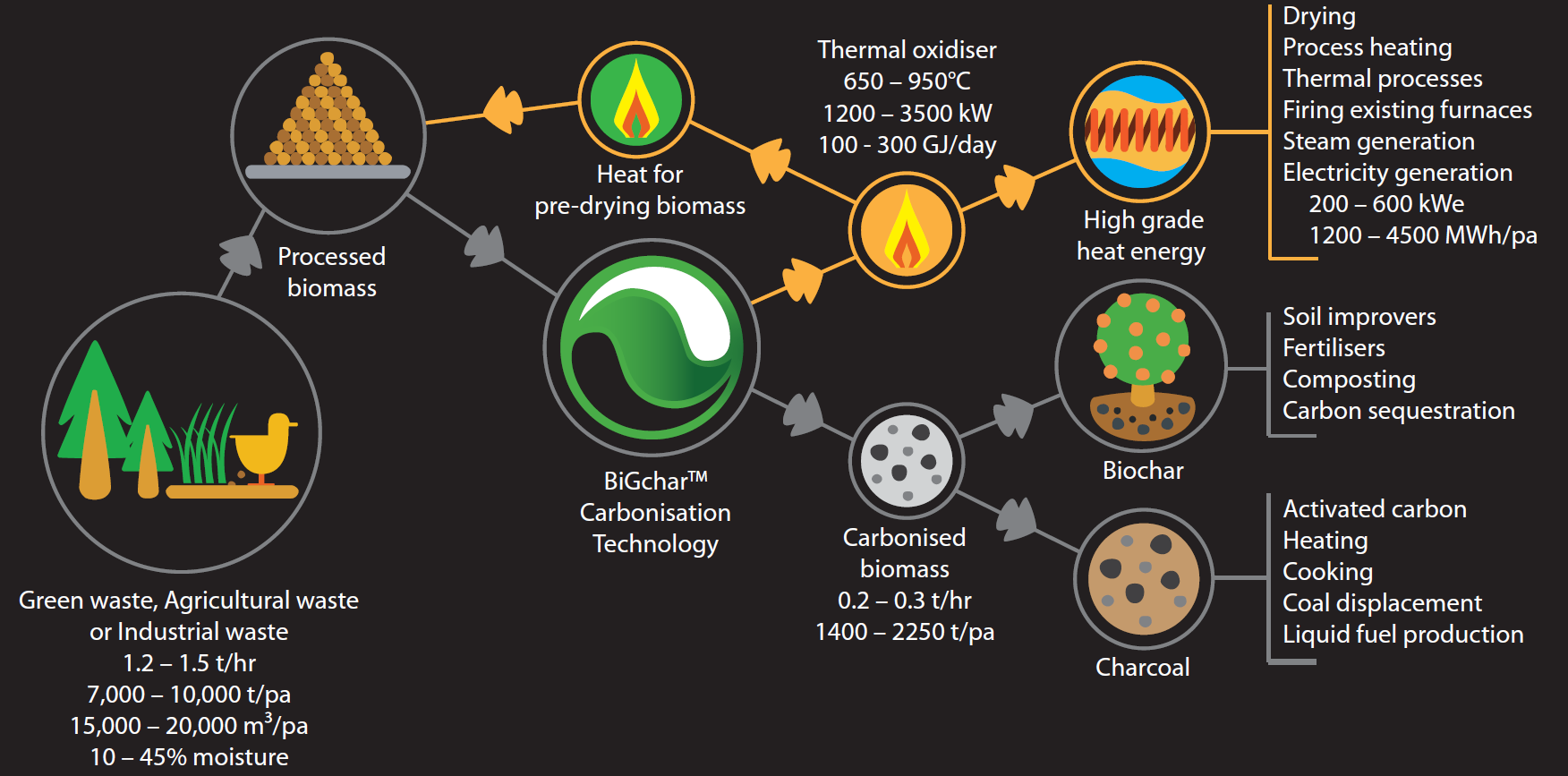

Charman was formed by Trevor Barrows (Charman) in 2011, after researching how to find a way of sequestering the carbon from the considerable biomass waste left after the Black Saturday fires in Victoria. This led to being involved in a team of engineers in the development and manufacture of the 1st commercial continuous pyrolysis biochar production facility in Australia since 2013.

Charman vision is to close the loop in returning organic clean waste biomass into the ecological life cycle of our planet by the economic production and sequestration of biochar.

Biochar Production

Primary feedstock for Charman Biochar is walnut shell, a nuisance biomass waste, sourced within 50km of the production facility.

The heat produced during this process is harnessed and used in place of gas or electricity to kiln a organic beer malt production facility adjacent to the biochar pyrolysis facility. Production is a continuous 24/7 operation. This ensures a high quality consistent biochar is produced with fixed carbon >85% and low ash content typically <5%.

Local Circular Economy

Overall heat energy and biochar production provides a net carbon footprint reduction in the production of organic malt used by a local brewery, negates waste methane emission from a nuisance waste, sequesters carbon for proactive garden, horticultural, bovine husbandry and host of over applications (reference page link).

Certifications

Charman Biochar is registered as an input for organic production, in which it is an ingredient for Easy As Organics, Home – Easy As Organics, living soil products.